PRODUCTION

Since its origins, in the eighties, the company has specialized in precision mechanics applied to the aeronautical sector (construction of equipment and aero engine parts).

Ar.Ter. S.r.l. owned by the Fornaro family for three generations, it is a consolidated industrial reality that operates in modern infrastructures in the province of Naples.

OUR EXPERIENCE

In recent years Ar.Ter. has acquired an important experience in:

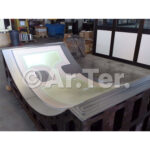

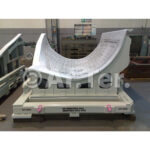

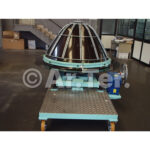

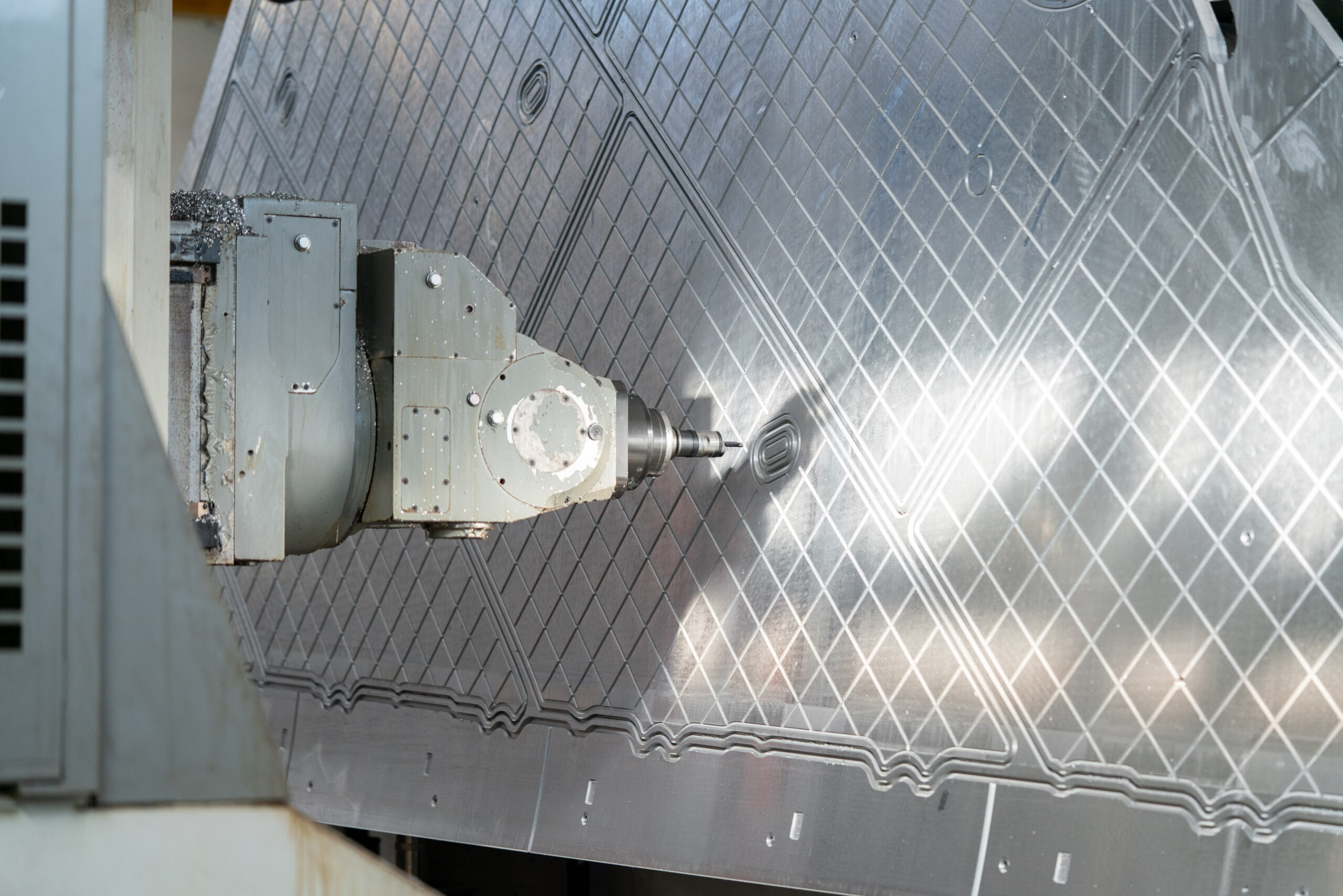

- Engineering, design and construction of aeronautical equipment

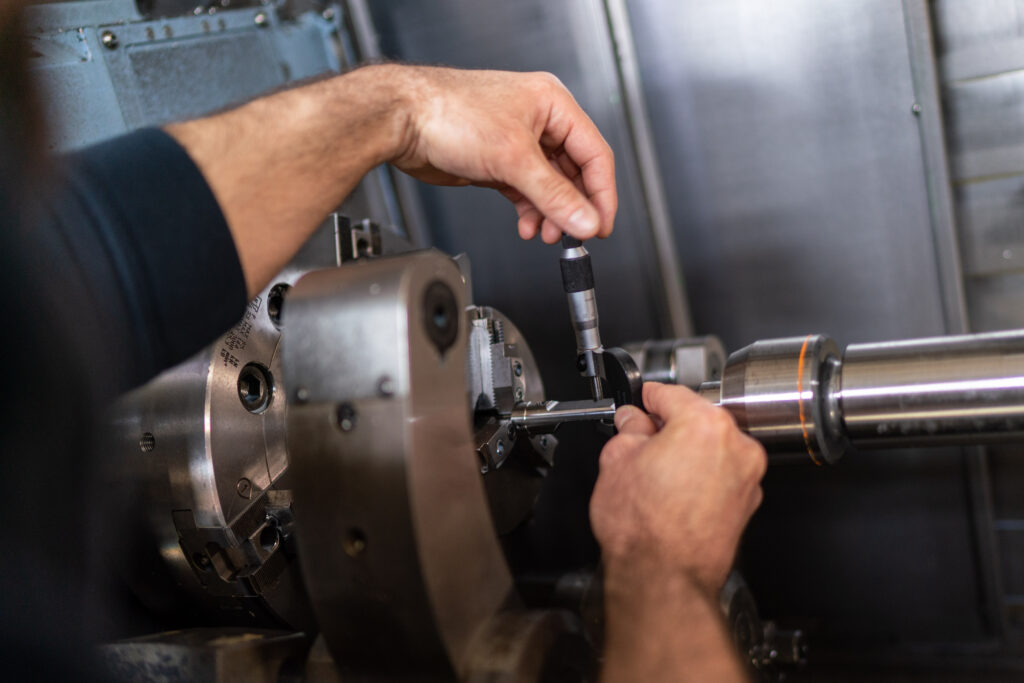

- Construction of aero engine parts

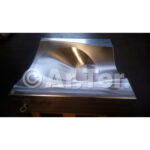

- Construction of aeronautical models and molds

- Construction of aeronautical landing gear structural components

- Construction of structural components of the fuselage and aeronautical wings

- Mechanical machining with special alloys, Inconel, Invar, etc.

- Construction of aeronautical hydraulic components

- Construction of aeronautical assembly yards

- Construction of railway traction and rolling stock components

- Construction of mechanical components for renewable energy plants.

- Special hard chrome plating process

- Special shot peening process

- Special process of EDM

In the last 40 years of experience, Ar. Ter. has acquired a high level of skills in the industrialization of equipment to support various processes, from concept, design, structural analysis, industrialization and production (and related controls), including special processes, in line with innovations in materials and in technologies, of critical parts and structural assemblies.

Ar.Ter. is known for large aeronautical manufacturing in special alloy, Invar, Inconel, etc.

The technical skills acquired over the years and the investments have allowed Ar.Ter. to be successfully engaged in the design and manufacture of equipment for important innovative aeronautical programs such as

Boeing 787, 767, Airbus A220, A380, A321, JSF, ATR, EFA, C27J,

M345, M346, Clean Sky, Clean Sky 2, etc.

Its offer was further intensified by providing engineering consultancy services to international partners (both remotely and face-to-face). Ar.Ter. can manage contracts in full supply or with materials on behalf of third parties.

Ar.Ter. can manage contracts in full supply or with materials on behalf of third parties.

Ar. Ter. use the CATIA CAD / CAM system integrated with MES/ERP system, this allows real-time information regarding planning, resource availability, budget, project status, cost monitoring.

For all activities not directly carried out internally, Ar. Ter. has a register of qualified and certified suppliers shared with its customers.